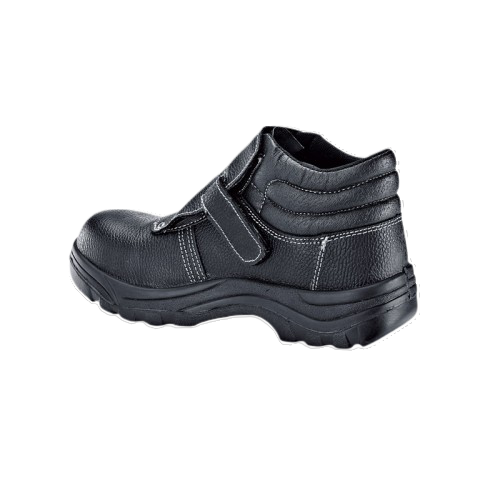

KUKKA Welding Safety Boots – Step into Superior On-the-Job Protection

For professional welders navigating the demanding environment of the forge, prioritizing safety is paramount. KUKKA Welding Safety Boots, distinguished by their superior protection, exceptional comfort, and unparalleled durability, empower you to tackle any welding project with unwavering confidence.

Uncompromising Safety:

Steel Toe Cap: Crafted from high-strength steel, the strategically placed toe cap shields your feet from falling objects, forceful impacts, and potential weld splatter, ensuring essential on-the-job security. This crucial feature complies with industry standards like ASTM F2413 (standard for protective footwear), safeguarding your feet from potential injuries.

Heat-Resistant Upper: The KUKKA boot boasts a meticulously designed upper constructed from heat-resistant materials like flame-retardant leather or fire-retardant fabrics. This critical safety element minimizes the risk of burns from sparks, splatter, or accidental contact with hot surfaces, promoting a safer work environment.

Puncture-Resistant Midsole: While not a standard feature on all models, some KUKKA welding boots might incorporate a puncture-resistant midsole, typically constructed from a robust material like Kevlar®. This valuable addition offers an extra layer of protection against sharp objects that may penetrate the shoe’s underfoot area, further enhancing workplace safety.

Comfort Meets Performance:

Unrelenting safety shouldn’t come at the expense of comfort. KUKKA welding boots are meticulously engineered to prioritize long-lasting wearability without compromising on essential protection features.

Breathable Lining: The interior of the boot often features a breathable lining that allows for optimal air circulation, preventing sweat build-up and keeping your feet cool and dry throughout your workday. This promotes enhanced comfort and reduces the risk of foot fatigue, especially during extended welding sessions.

Supportive Midsole: The ergonomically designed midsole provides exceptional arch support and shock absorption, minimizing stress on your feet, ankles, and knees. This translates to reduced fatigue and a more comfortable work experience, especially when standing or crouching for long periods.

Electrical Hazard Protection (Optional): Specific KUKKA welding boot models might be electrically rated, safeguarding wearers from potential electrical hazards. These boots are typically constructed with non-conductive materials in the sole and other critical areas to minimize the risk of electrical shock. This additional safety feature is particularly relevant for welding environments where electrical equipment is present.

Enhanced Functionality:

KUKKA welding boots go beyond basic protection, incorporating additional features that elevate your welding experience:

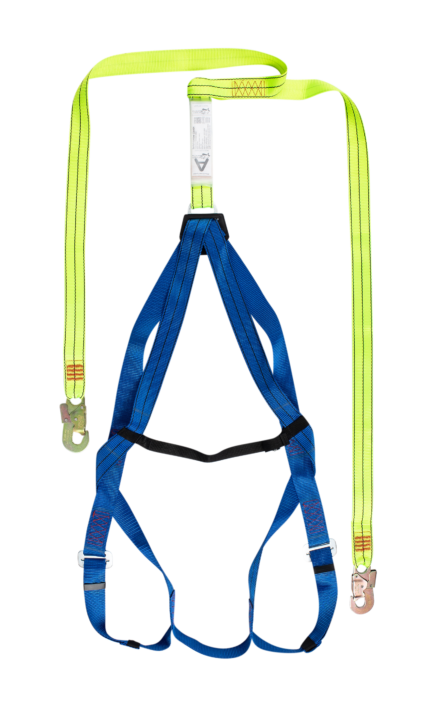

Spat Attachment: The included spat acts as an essential barrier, shielding your ankles and shins from hot sparks, molten metal splatter, and UV rays emitted during the welding process. This detachable component offers increased protection and flexibility, allowing for easy removal when not required.

Lace-up Closure: A sturdy lace-up closure system provides a secure and customizable fit, ensuring the boots stay firmly in place during dynamic movements and various welding positions. This promotes stability and prevents the boots from slipping off, even in fast-paced work environments.

Ankle Support: The boot’s design often prioritizes ankle support by incorporating features like a higher-cut upper or padded ankle collar. This helps minimize the risk of ankle sprains or injuries, especially when working on uneven surfaces or navigating cluttered welding areas.

Additional Considerations:

MOQ 1: The KUKKA Welding Safety Boot is available for purchase in single quantities (MOQ 1), catering to individual welders or those seeking to try out the product before larger-scale adoption.

Durability: KUKKA prioritizes using high-quality materials and construction techniques to ensure the boots’ durability and longevity. This translates to a cost-effective investment, as the boots are built to withstand the demanding conditions of a welding environment.

Variety of Options: KUKKA might offer a variety of welding boot models with different features, materials, and functionalities. This allows you to choose the boot that best suits your specific welding needs and preferences.

Invest in Your Welding Safety:

Equipping yourself with KUKKA Welding Safety Boots demonstrates your commitment to prioritizing safety in the welding environmentKUKKA Welding Safety Boots: Frequently Asked Questions (FAQs)

This section addresses common questions you might have about the KUKKA Welding Safety Boots:

What safety certifications do the KUKKA welding boots meet?

The specific certifications may vary depending on the model. However, KUKKA prioritizes safety and strives to comply with industry standards relevant to welding footwear. Common certifications for welding safety boots include ASTM F2413 (standard for protective footwear), EN ISO 15034 (European standard for welding footwear), and CSA Z195 (Canadian standard for protective footwear). It’s always recommended to check the specific model information for detailed certification details.

Are there different styles of KUKKA welding boots available?

While core functionalities remain consistent, KUKKA might offer various styles within the steel toe and spat category. These variations might include:

* **Boot Height:** Choices may include ankle-high boots for better mobility or knee-high boots for enhanced protection.

* **Lacing vs. Pull-on:** Lace-up styles offer a more customizable fit, while pull-on styles are convenient for quick on and off.

* **Sole Options:** Some models might provide different sole options, such as heat-resistant rubber soles or slip-resistant outsoles, catering to specific welding environments.

How do I choose the right size for KUKKA welding boots?

KUKKA recommends consulting a size chart provided on their website or packaging. It’s generally advisable to consider a half-size larger than your typical shoe size to accommodate for any necessary work socks or insoles.

How should I care for my KUKKA welding boots?

Refer to the manufacturer’s instructions for specific care guidelines. Generally, proper care involves brushing off dirt and debris after each use. You can use a damp cloth and mild soap to clean the exterior if necessary. Allowing them to air dry completely is crucial to prevent moisture build-up. Store them in a cool, dry place when not in use.

Can I replace the insoles in my KUKKA welding boots?

Yes, many KUKKA welding boots feature removable insoles that can be replaced with custom orthotics or other preferred insoles for enhanced comfort and support.

What is the warranty on KUKKA welding boots?

The warranty period for KUKKA welding boots may vary depending on the specific model and retailer. It’s recommended to check the product information or contact the seller for details regarding the warranty coverage.

By incorporating this FAQ section, you provide potential buyers with valuable information and address their concerns, fostering trust and increasing the likelihood of a purchase.

KUKKA Welding Safety Boots: Applications and Industries

The KUKKA Welding Safety Boot caters specifically to the welding industry, where foot protection is paramount. Here’s a breakdown of its suitability:

Arc Welding: KUKKA boots shield welders from sparks, splatter, and heat associated with various arc welding processes like Gas Tungsten Arc Welding (GTAW), Shielded Metal Arc Welding (SMAW), and Flux-Cored Arc Welding (FCAW).

Oxy-fuel Welding: The heat-resistant properties of the boot safeguard against heat hazards encountered during oxy-fuel cutting and brazing applications.

Plasma Cutting: The splatter protection offered by the boots is crucial when working with the intense heat and molten metal generated during plasma cutting processes.

Beyond these specific applications, the KUKKA Welding Safety Boot can benefit any welder who prioritizes:

Foot protection from falling objects and impacts

Heat resistance against sparks, splatter, and hot surfaces

Electrical hazard protection (optional feature)

Enhanced ankle support and stability

Durability for long-lasting use in demanding environments

By highlighting this targeted application, you effectively communicate the KUKKA boot’s value proposition to its core audience: professional welders seeking optimal protection and performance in their trade.

KUKKA Welding Safety Boots: Standing Out From the Competition

While the core functionalities of the KUKKA Welding Safety Boot are undeniable, there are additional aspects worth considering that elevate this footwear solution beyond the competition:

Advanced Comfort Features: Some KUKKA models might incorporate advanced comfort features like moisture-wicking lining that actively draws sweat away from the foot, promoting dryness and reducing the risk of blisters. Additionally, antimicrobial technology can be integrated to combat odor-causing bacteria, ensuring long-lasting freshness.

Customization Options: Beyond the standard lace-up closure, some KUKKA boots might offer additional customization options like replaceable insoles for personalized comfort and adjustable ankle straps for a more secure fit.Commitment to Quality and Innovation: KUKKA prioritizes using high-quality materials and construction techniques to ensure the boots’ durability and longevity. This translates to a cost-effective investment, as the boots are built to withstand the demanding conditions of a welding environment. Additionally, they continuously strive to integrate the latest advancements in welding footwear technology, offering their customers cutting-edge safety solutions. Here are some potential examples:

* **Heat-Resistant Lacing Systems:** Some KUKKA models might incorporate **heat-resistant laces** that minimize the risk of melting or burning during exposure to welding heat, further enhancing safety.

* **Metatarsal Protection:** Specific models might offer additional **metatarsal protection**, safeguarding the top of the foot from potential impacts from falling objects or dropped tools.

* **Reflective Elements:** For enhanced visibility in low-light welding environments, some KUKKA boots might include **reflective elements** integrated into the design.

By mentioning these potential advanced features, you showcase KUKKA’s dedication to continuous improvement and their focus on providing welders with the most comprehensive and innovative safety footwear solutions.

Conclusion: Why Choose KUKKA Welding Safety Boots?

KUKKA Welding Safety Boots represent a compelling choice for professional welders seeking a balance between uncompromising safety, exceptional comfort, and long-lasting durability. Here’s a recap of the key benefits:

Superior Protection: Steel toe cap, heat-resistant upper, optional puncture-resistant midsole (on some models), and electrical hazard protection (on specific models) safeguard your feet from potential hazards.

Enhanced Comfort: Breathable lining, supportive midsole, and various fit options like lace-up closure and removable insoles promote comfort during extended wear.

Increased Functionality: Spat attachment shields your ankles and shins, while features like ankle support and slip-resistant outsoles (depending on the model) enhance overall functionality.

Durability and Value: High-quality materials and construction techniques ensure the boots withstand demanding environments, offering a cost-effective investment.

Commitment to Innovation: KUKKA continuously explores advanced features like heat-resistant laces, metatarsal protection, and reflective elements to elevate safety and user experience.

Invest in your safety and performance. Choose KUKKA Welding Safety Boots today!

By incorporating this concluding section, you provide a clear and concise summary of the KUKKA boot’s value proposition, encouraging potential buyers to make an informed decision. Remember to maintain a natural tone throughout the description and prioritize providing valuable information to the reader.

Help Center

Help Center

Reviews

There are no reviews yet.